The overlooked major player of dairy success: Adequate temperature control

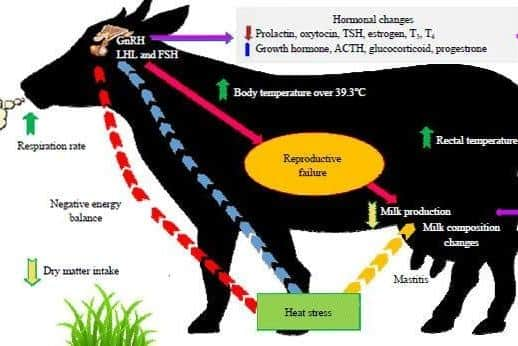

Lower milk yields, depressed feed intakes, reduced fertility and increased mastitis levels are all consequences of this, and the associated cost continues to grow as global temperatures increase.

According to US dairy consultant Michael Wolf UK dairy farmers could be getting 3-4 litres more milk per cow everyday by investing in adequate ventilation and improving cow health.

Advertisement

Advertisement

“Farmers do a great job of making sure they have got the right cubicles, bedding and feed, yet they often don’t think about ventilation. AHDB ventilation expert David Ball agrees ventilation is key in sustaining productive dairies year-round ‘it’s all about air movement and drawing fresh air into cow buildings”.

Most herds to some degree experience heat stress every year and due to the role played by humidity, cows can start feeling the effects of heat in spring when temperatures are relatively low. This costs producers by reducing milk production, reproductive performance and increasing rates of culling.

David continued: “The first thing a cow does is stop eating which decreases the availability of nutrients used for milk synthesis, although following periods of warmer temperatures there is usually a lag before milk yield declines and milk composition alters. Secondly, she spends more time standing, putting additional pressure on her feet.”

The provision of cooling to cows under heat stress conditions is essential by resulting in more animals ruminating, maintained milk yield, and decreased body temperatures compared with uncooled animals. Dr Wolf calculated if farmers got a yield loss of 2.25kg a cow a day over a six week period in a 400 cow herd and with a milk price of 0.25p that equated to a loss of £9,400 over the six weeks.

Advertisement

Advertisement

Some producers may not see the signs at the time but will see a dip in herd fertility a few months later, says Harper Adams dairy specialist Emma Bleach. This is because heat stress experienced by a cow depends on both temperature and relative humidity. A humidity of 68 or above indicates that a high-yielding cow will typically experience heat stress. This level is already reached with a combination of an ambient temperature of 22oC and a relative humidity of 60%.

Elevated environmental temperatures reduce both the duration and intensity of oestrous expression which some believe is caused by the reduction in dry matter intake and consequently nutrients, depletes oestrous behaviour by reducing hormone production. Dr Wolf’s research demonstrates a 0.5C increase in uterine temperature one day post-insemination is enough to reduce conception rates by 7%.

Furthermore a Florida study demonstrating that cows cooled during the hot weather period maintain better bodyweight, allowing for better performance post-calving. In addition, calves born to cooled dry cows were heavier, healthier, and performed better during their first lactation.

There is agreement between researchers that mechanical ventilation has a positive impact on summer milk yield compared with natural ventilation, and that ventilation was determined to be significantly better than no ventilation economically by decreasing respiratory rate, rectal temperature and increasing DMI.

Advertisement

Advertisement

Considering the high level of investment involved in installing a ventilation system, the chosen system must be energy efficient and active more than half of the year. The Italian market has previously encountered this dilemma, and is now recognised globally as the leader in livestock ventilation technologies, working in partnership with farmers to verify their ventilation success on commercial livestock farms. Fan systems are now available, featuring a reservable motor which is, used for circulating warmer air in winter, proven to dry bedding and minimise mastitis risk and, also reduce ammonia levels improving its feasibility versus other ventilation systems.

Successes of Italian Fans on UK Farms

Fans are growing in popularity particularly the high-volume low speed ceiling fan (HVLS) models. Traditional box fans are losing favour compared to the HVLS which is effective at moving air both in and out of, as well as around the building.

The low energy Italian HVLS fans which are quiet and efficient to run are now available on the UK market. These are equipped with sensors and can be programmed to kick in as temperatures and humidity levels begin to creep up. These fans are in place on the farm of Herefordshire based producer Henry Lewis who runs a 900-cow herd on a high welfare indoor system in partnership with his wife Sue and son James. Herd average yield is ~12,000 litres, 4.12% butterfat and 3.25% protein. Henry is aware of the importance of cow comfort and mitigating the impact of heat stress. Henry commented: “I hate to see heat stress in cows, and it was a problem on our unit, as soon as temperatures hit the mid-20s. At 22oC we saw cows standing around, close to water troughs so we knew they were feeling it.

“Cow health and welfare is paramount in our business. Keeping cows cool is vital and, for our unit, fans are key in ensuring housing is comfortable and conductive to achieving high yields” he says. Mr Lewis has several HVLS CMP fans in cow housing mounted on the roof They also have temperature control sensors and are set to kick in at just 8oC. ‘Just turning slowly but enough to help air movement in the building. They’re working all year round.

Advertisement

Advertisement

“Prior to installation it was typical to see intakes and milk yields drop, reduced bullying activity and signs of oestrus and even cases of acidosis as spring and summer temperatures took their toll on the herd. Now the older buildings have traditional fans which do the job, but Mr Lewis says the HLVS fans in the newer cow housing are really making a difference keeping cows cool, comfortable and milking efficiently.

“Fan speed increases in line with temperature and humidity they’ve made a huge difference but they’re extremely quiet so the cows are not disturbed but can enjoy the cooling benefits” says Mr Lewis. “We’ve noticed how much more pleasant and airy the buildings are to work in.”

There are opportunities for improved cow cooling on every farm, as David Ball says most herds experience heat stress to some degree every year, and each producer must assess the immediate financial benefits ventilation can deliver for his business, and the long-term benefits for his herds genetic advancement.

See advert on page 38.