Something's brewing at Murlough Bay

It was the start of a life-long passion which eventually led to the establishment of Glens of Antrim Craft Ales and Beers.

The business is located on the family farm at one of the Causeway Coast and Glens most scenic locations. The road to the house is used more by sheep than vehicles, with breath-taking views across to Rathlin Island and the Mull of Kintyre. Most definitely off the beaten-track, but the perfect backdrop for a truly handcrafted product.

Advertisement

Advertisement

The brewing process takes place every week in a converted garage. The main equipment is a number of recycled milk tanks – a big leap forward from the large jam saucepan which Pat previously used.

Along with his wife Isabella and the help of two-part time employees, the entire process from brewing to bottling is carried out on site.

“It’s remote here, as you can see, so I had to find something to do!” laughs Pat. “We are one of the few breweries to do it all in-house. We can stand behind our product and say that this is a true craft beer,” said Pat.

And while there may be no mobile phone signal or WiFi at Murlough Bay, there’s a constant supply of a very vital ingredient – fresh spring water.

Advertisement

Advertisement

This forms the basis of the McCarry’s products – and they believe it is key to setting their beer apart.

Isabella said: “It’s been drank here since the 1700s, and it makes a huge difference to taste no matter if you’re making tea, bread or beer. There’s just no comparison.”

Another essential element in the brewing process is time. The beer isn’t rushed along – it takes around six weeks from brewing begins before it’s poured into its final resting place.

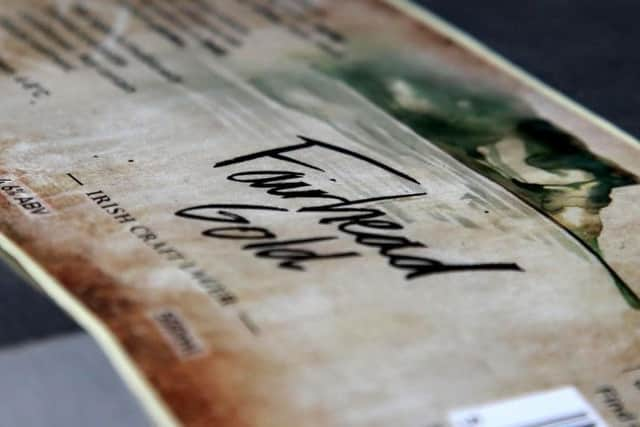

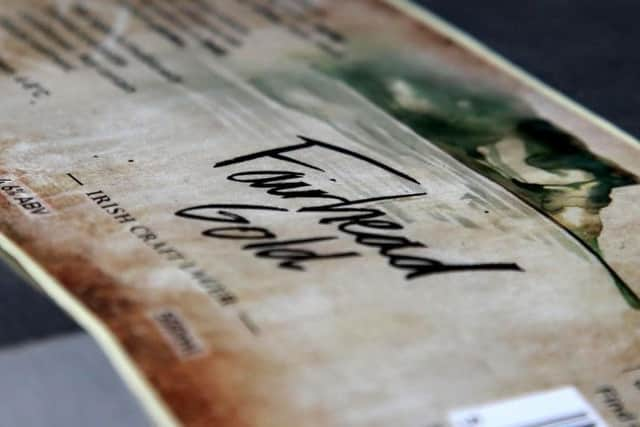

The brown glass bottles are stacked in an area next door to the garage, and even their labels have a story behind them.

Advertisement

Advertisement

They were designed by Maria McGinn, a former pupil of Isabella at Cross and Passion College in Ballycastle. Using water colours and ink, her works of art are another unique aspect of the products. Each label reflects the name of the three brews currently on offer – Fairhead Gold, Rathlin Red and Lizzie’s Ale.

The latter is the only one which may need some further explanation. Named after Pat’s great aunt Lizzie who lived on the family farm, it features an image of a bright yellow daffodil. This is in homage to the many flowers which she planted, and which continue to bloom on the farm every year.

Pat’s recipes are now fine-tuned to perfection but the self-taught brewer says it was an on-going case of trial and error to reach this stage.

The creation of a finished product free of any cloudiness, is achieved by adding in a dried version of carrageen moss. The seaweed enjoys a reputation as a natural remedy for many ailments and conditions, including respiratory problems. In the brewing process, it acts as a fining agent, leaving behind a product which Isabella describes as ‘natural and clean’.

Advertisement

Advertisement

As previously mentioned, Isabella fits her time as a brewer around her job at Cross and Passion College where she is Head of History. It’s also a part-time vocation for Pat, who continues to run the 450 acre farm with its stock of sheep and suckler cows.

“It’s a diversification process for us. At the minute, the brewery is our secondary income but we think we could reverse that so farming takes up that position. Hill farming is slowly dying out, and most families involved in it now have an alternative income. It’s hard to get help now as well – people don’t want to get work on a farm,” said Pat.

So while there is no doubting the beauty of the farm and its stunning location, this brings its own difficulties which Pat and Isabella are seeking to address through their brewing industry.