N-Sensor improves Nitrogen efficiency

This can improve fertiliser and agrochemical (slurry) efficiency to produce better crop yields, better crop quality and at the same time give better environmental outcomes.

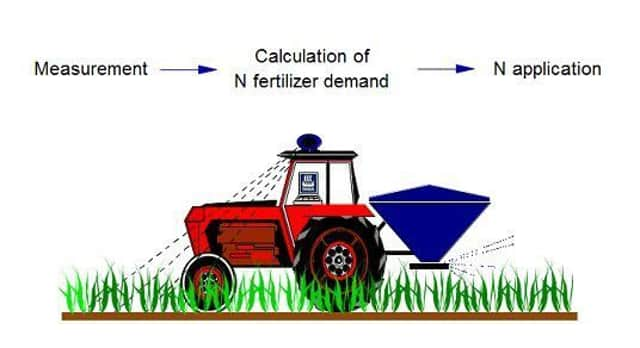

Simon Robbins from Precision Decisions detailed how the Yara N-Sensor offers farmers a solution to real time variable rate nitrogen applications by adjusting rates according to crop growth while travelling across a field. It bases its measurements on specific wavelengths of light to establish exact levels of biomass and colour within the leaf.

Advertisement

Advertisement

As a result, the N-Sensor is designed to deliver precise levels of input according to crop requirements, helping to reduce environmental effects whilst maximising potential profits.

The N-Sensor was first developed by Yara’s Research and Development team at Hanninghof in Germany following over 10 years of intensive testing and trial work.

It was introduced on farm in the 1990’s offering a practical solution to farmers for variable rate nitrogen applications. Using an oblique view of the crop, its nitrogen demand is measured by the N-Sensor mounted on top of the cab using crop specific light reflectance.

Within a fraction of a second, the data is translated into an application rate which adjusts the sprayer/spreader accordingly.

Advertisement

Advertisement

The N-sensor results quoted by Yara are based on the longest running, most comprehensive set of fully replicated trials in the industry. These have mainly involved arable crops, but increasingly they are looking at grass. These trials show yield increases of up to 3.5%, reduced lodging, more even grain quality across the field and up to 20% increased combine efficiency with on average a 18.5% reduction in harvest days. This all means more efficient use of nitrogen, enhanced and more even grain protein content and therefore increased gross margin and profitability.

On grassland it has shown improved yields of typically two tonnes of DM/ha on first cut and 0.7 tonnes on second cuts. On grass N-Sensor has detected areas of the field with different nitrogen supply due mainly to different slurry levels and different types of slurry.

Trials showed the optimum nitrogen rate for first cut silage varied substantially from 60 to 165 kgN/ha. (48 to 130 units/ac). Clearly a flat rate fertiliser application is not the most appropriate due to this variation, so again there must be improved efficiency from both slurry and fertiliser nitrogen by adjusting rates with more uniform protein levels and fermentation quality within the silage area.

Using the same technology, N-Sensor has the only Absolute-N calibration for oilseed rape, proven to deliver a 3.9% increase in yield. Unlike other systems available from machinery manufacturers, the development and performance of the N-Sensor is underpinned by Yara’s industry leading agronomic knowledge and insight.

Advertisement

Advertisement

Trial work has also confirmed that N-Sensor can be used to reduce the application of Plant Growth Regulators, potato haulm desiccants and potentially fungicides.

To help customers get the most from their N-Sensor, Yara provides high quality complete compound fertiliser and hands-on agronomic and technical support throughout the season.

To this end Chloe Kyle of Yara will be present at Lindsay Agri of Downpatrick, Amazone fertiliser spreader open day on 8th November to discuss the benefits of N-Sensor on your farm and in conjunction with any variable rate spreader purchased.